BST-368 Four bars chain stitch multi needle computerized quilting machine

Technical Parameters:

| Spec \ Model | 100 inch | 120 inch | ||

| BST368M-L100 | BST368M-L120 | |||

| BST368-L100 | BST368-L120 | |||

| Max.Fabric Width | 2700mm | 3100mm | ||

| Max.Bar Arrangement Width | 2540mm/100 inch | 3048mm/120 inch | ||

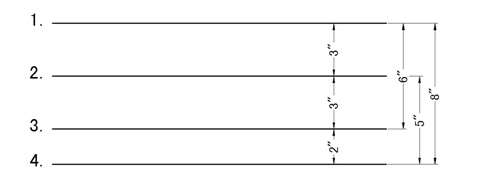

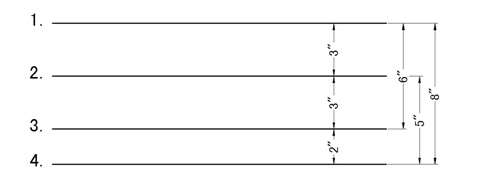

| Bar Interval |

2 inch 3 inch 5 inch 6 inch 8 inch ( 50.8mm 76.2mm 127mm 152.4mm 203.2mm) |

|||

| Needle Spacing | 25.4mm/l inch | |||

| Carriage Travel | 460mm/18 inch | 400mm/16 inch | ||

| Max.Tack&Jump Dia | 460mm/18 inch | 400mm/16 inch | ||

| Speed | 1000RPM | |||

| Air | 0.4-0.8Mpa | |||

| Tank Cap | 70L | |||

| Weight | 8500kg | 9500kg | ||

|

output380V 3P/50Hz |

BST368M-L90/L100/L120 | 13.5KW | ||

| BST368-L90/L 100/L120 | 12KW | |||

| Needle | Groz-Beckert De794H | 180#(24) 160#(23) 140#(21) 120#(19) | ||

(No need of back additional automatic cloth-roller in the back of BST2212 cutting machine).

Features Introduction:

1.The width of needle-bar is 100 inch, the interval of needles is 1 inch.

2.Create multi 4 needles bar arrangement Four needle-bar arrangement, the interval of needle-bar are:2″、3″、5″、6″、8″。

3.The width of movement for the platform is 450mm (16inch).

4.The max diameter of independent design is 450mm (16inch).

5.Speed: 1000 RPM

6.Voltage: Three phase 380V 50Hz Power: 13Kw

7.Pressure: 0.8Mpa

8.Weight:9 tons

9.Using Groz-Beckert 794H needles: 120#(19)、140#(21)、160#(23)、180#(24).

10.Ps: Quilting the independent designs on the thick sponge fabric can all use 120#(19)needle. Equipped with advanced anti-fly -line device for shear the line when quilting patterns

11.The thickness of the quilting sponge is 0.3cm to 8.5cm high-density sponge. (can quilt monolayer polyester wadding and chemical fiber cotton)

12.Arrange front sponge-shelf and back rolling device(sponge-shelf contains brake device, it can adjust the sponge itself; and the end of sponge-shelf can put on the ground, it’s convenient for someone to pick up the sponge).

13.Use Japanese YASKAWA latest servo motor, the speed is four times faster than the old one.

(Model: SGMGV—13ADA61)

14.The computer has nearly 700 patterns on different sizes, it can save lots of different patterns.

15.Suitable working temperature: -30 ° to 50 °.

16.Then machine contains 5Kw special transformer for servo motor inside, the outside manostat is responsible for the customer.

17.X axis, Y axis and Z axis are drived by exact gear box system, it makes the patterns distorted less and achieves the prefect effect.